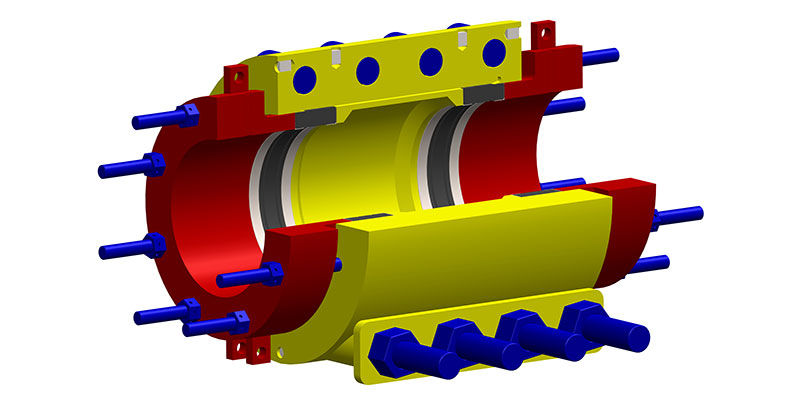

Carbon steel split sleeve is thoroughly used to fix a course of action of high or low weight and high or low-temperature pipeline structures, including oil, water, gas, steam, and compound systems. Stuns join the bits of the snap to shape a high-reliability pressure vessel around the hurt or spilled pipe.

Fixing is given by molded elastomer seals of the most fundamental consistency, chose for consistency with pipeline liquid and working temperature. These sleeves may in like way be welded to turn out after establishment to be a steady seal if conditions legitimize the extra expense.

A carbon steel split sleeve is a key piece of our blueprint of things for the flourishing of pipelines. The snap thing offering can be sold self-rulingly or in a wide blend of sizes, evaluations, and courses of action as an extra to more prominent fix structures.

A carbon steel split sleeve adds another estimation to the blessed and perpetual fix that pursues your pipeline. They are utilized to fix high and low weight and temperature pipelines – around the sea and inland – that pass on oil, gas, rage, compound systems, and water. Click here for API 5L Pipe Sleeve.

PROPERTIES OF CARBON STEEL SPLIT SLEEVE

The Carbon steel split sleeve fastens are the necessary working weight, completely static-tried hydro to 1.3 occasions. All Clamps are prepared utilizing a half-inch vent port, contingent upon the size and prerequisites and conclusions of the client. The sleeves are made altogether as controlled by the API. They react to customers’ data and the preconditions for the business structure. Our sleeves are completely anything besides difficult to consolidate and wear. They were proposed to be effectively presented and speedily repairable with the most conventionally open instruments.

MATERIALS USED FOR CARBON STEEL SPLIT SLEEVE

Carbon steel split sleeve cuts are made by the materials that the customers require. The materials used are of an impeccable quality which fits in with the subtleties of the business. Weight classes ANSI 300, 400, 600, 900, and 1500 are incorporated. Structure checking and stress examination were finished using body fragments that are reasonable for commonly dangerous workplaces. Simply support rings can be mounted by the specifics of the clients. Twofold line fixing arrangement is used in circumstances where pipeline spillage is over the top costly like the case in pipelines passing on gases.

ASTM A283 GRADES : Grade A , Grade B , Grade C , Grade D.

ASTM A285 GRADES : Grade A , Grade B , Grade C.

ASTM A387 GRADES : Grade A , Grade B , Grade C , Grade D.

CARBON STEEL SPLIT SLEEVE MATERIAL SPECIFICATIONS

- ANSI pressure classes 300, 400, 600, 900 and 1500

- The arrangement was reliant on: ASME Sec. VIII, API 6H , ANSI B31.4, B31.8 and Carbon Steel Split Sleeve Software 3S)

- Arrangement control and stress examination with Finite Element Package

- Body materials: A216 WCB, A216 WCC, A352 LCC, A516 Gr.70 (Suitable for routinely dangerous organizations)

- Stud material: A193 Gr. B7, Nut material: A 194 Gr. 2H

- Covering: Yellow Epoxy Polyamide, standard or Marine epoxy

- The most noteworthy gauge NBR or VITON elastomer seal certainly great with the line fluid and incorporating temperature will be brought into the Carbon Steel split sleeve NBR temperature run is from – 20 C to + 80 ̊ C̊

- HNBR temperature run is from – 20 C to + 150 ̊ C̊

- VITON temperature go is from – 20 C to + 200 ̊ C

- Gaskets are replaceable with no extraordinary instruments.

- Support rings can be presented upon cleints request.

- Twofold Row Sealing (DRS) plan is moreover available.

- This remarkable structure is logically sensible for where likely spillage is a great deal of extravagant or unsafe, for instance, vaporous organizations and offshore applications.

WELDABLE CARBON STEEL SPLIT SLEEVE

Once conveyed, the two braces can be suitably fitted for (welding method is accessible on demand).

The warmth protectors (corresponding to seals) shield seals from heat as the sleeves are welded onto the tubing.

PRODUCTION OF CARBON STEEL SPLIT SLEEVE

All Carbon steel split sleeve might have the option to weld after the arrangement. They are confined from radiation during the welding of the tops towards the channel heat encasings running corresponding to the seals. We will make these cinches of longer lengths if the clients so offer.

CUSTOMIZATION

A carbon steel split sleeve is made by the necessities of the customer. For eg, all parts, for example, body material, carbon steel/tempered steel, studs, and nuts for applications similarly as seal items are of stunning quality and are strong when the like buyer requires.

MARKING & SHIPPING

A carbon steel split sleeve is made by the preconditions of the client. First off, all the parts, body material, carbon steel/rewarded steel, studs, and nuts for applications, for example, seal materials are of superb quality and are strong and serious with purchaser needs. Reli Sleeve avails it’s products all across India and various countries abroad as well.

BENEFITS

-

- Can be utilized when pipelines run out or when separator debilitating happens

- These are self-fixing, got by screw snap studs

- Standard catches come in one seal game-plan yet twofold seal plan can be given on demand

FEATURES

Average cuts are outfitted with an elastomeric seal made of Buna-Nitrile or Viton. The fixing load is developed for these applications by tensioning the snap studs with stuns (Carbon steel split sleeve plan)

All Clamps are composed with an outside weight test office, which picks the joint constancy before assigning

During establishment, the twin seal course of action is additionally accessible to permit inside testing.

Supports might be obliged both topside and subsea fix applications.

DESIGN STANDARDS AND SPECIFICATIONS

-

- ANSI pressure classes 300, 400, 600, 900 and 1500

- Design based on API 6H.

- Design calculation ASME Sec. VIII Div. I

- Body materials: A216 WCB, A216 WCC, A352 LCC, A516 Gr.70 (Suitable for normally corrosive services)

DESIGN FEATURES AND METHODS

Safety

The snaps are completely compensated weight vessels, the degree of work weight being hydrostatically assessed at 1.3 occasions (as accommodated in Section VIII Div.1 UG-99 of the ASME)

A port with 1 “NPT vent is trailed by the two Clamps.

Design Criteria and Industry Standards

Both Carbon steel split sleeve are checked as per API Specification 6H, “End Closure Specification, Connectors and Swivels,”

Weight VESSEL CODE, Section VIII; and with ANSI codes B-31.3, B31.4, and B31.8, where fitting.

Settlement: In 10204 3.1

Ease of Installation and Maintenance

The Carbon steel split sleeve is outfitted with the most widely recognized gear required for establishment and is promptly accessible for field fix, including full seal substitution.

Economy

The motivation behind the Carbon steel split sleeve Repair Sleeve is to smooth out arrangement methods and parts utilizing forefront propels, bringing about lower weight, lower contorting rehearses, and a continuously moderate one.

CARBON STEEL SPLIT SLEEVES ARE COMPATIBLE WITH SOUR ENVIRONMENT

Every sleeve type is intended for use in the activity of hydrocarbon-bearing hydrogen sulfide ( H2S). The body substance follows NACE MR0175 for secure establishments.

CERTIFICATION AND TESTING

Non-Killing Test (NDT):

100% Particle Magnetic Inspection (MPI) for Stiffener to Shell

Warm-up (fillet)

100% Ultrasound testing of the welded vent plug

100% MPI welded hinge welds

Hydrotest as per Clause UG-99 of ASME Section VIII Div.1

TECHNICAL DETAILS

- Size: Regular repair pads: 4 – 52″ for 1500# ideal for temporary applications in carbon steel

- Size: 1⁄2 “– 52” > 2500 # Engineered Repair Clamps suitable for temporary or permanent carbon steel, stainless steel and super duplex applications

DESIGN CRITERIA AND INDUSTRY STANDARDS

- All SSRC’s are tested in accordance with the API Specification 6H, “Specification for End Closures, Connectors, and Swivels” and ASME BOILER AND PRESSURE VESSEL CODE, Section VIII, and with ANSI standards B-31.3, B31.4, & B31.8, where applicable. Visions 1 and 2.

- API SPEC 5L, Specification for Line Pipe

- ASME Pressure Vessel Code, Section VIII

- ASME/ANSI B18.2.1, Square and Hex Bolts and Screw Inch Series

MATERIALS

| Material Specification | ||

| Item | Designation | Material |

| 1 | Body Material | A216 WCB, A216 WCC, A352 LCC, A516 Gr.70 |

| 2 | Stud Bolt | A193 Gr. B7 |

| 3 | Nuts | A 194 Gr. 2H |

| 4 | Gaskets | NBR or Viton |

| 5 | Coating | (Marine) Epoxy |

CARBON STEEL SPLIT SLEEVE MATERIAL

| Material: | ASTM A 516 Gr.70 / ASTM A 105 |

| Fasteners: | ASTM-A-193-B7 & ASTM-A-194-2H |

| Seal: | Buna “N‟ |

| Paint: | Epoxy Coating Yellow 100 Microns |

| Vent Port + Plug: | Yes Lifting Lug (8” & above) |

| Hinge Assembly: | (8” & above) Yes |

| Design Temperature: | 65ºC N.D.T. |

| 100% RT Butt Weld | 100% U.T. of vent plug welds. (Fillet) |

| 100% MPI of Hinge welds (Fillet) | |

| Certification: | EN 10204 3.1 |

| Design Calculation: | ASME Sec. VIII Div. |

DESIGN CALCULATION

- ASME-Sec.-VIII-Div.-I,

- Certification-EN-10204-3.1:

NON DESTRUCTIVE TESTING (NDT)

- 100 % magnetic particle inspection (MPI) for stiffener to shell weld (fillet)

- 100 % ultrasonic testing of vent plug welds

- 100 % MPI of hinge welds

- Hydro test as per ASME Section VIII Div.1 clause UG-99

EASE OF INSTALLATION AND MAINTENANCE

- The sleeves are intended to be gathered with the most widely recognized hardware accessible and can be effortlessly fixed from the field with a total elastic seal.

- CARBON STEEL SPLIT SLEEVE INSTALLATION

- Give sufficient space to mounting the half sleeve onto the base of the tubing over the term. The base size for this is 0.75D.

- Wash the channel the Repair Sleeve pipeline was to be introduced on.

- Oil the surfaces that will be in contact with the gasket of the Carbon steel split sleeve

- Mount the top shell, and the screws, in the shorter openings.

- Every half-sleeve is separate at the foot. Insist the name is on the practically identical sider. Lift the lower sleeve and match the stuns over the smaller bit of the sleeve lip.

- Fix the screws, and if key tie the base of the Pipeline Repair Jacket.

SAFETY

The clasps are totally compensatory pressure vessels, hydrostatically attempted to 1.3 events the assessed working weight (as indicated by ASME Section VIII Div.1 arrangement UG-99)

All Clamps are equipped with a 1″ NPT vent port.

ECONOMY

Carbon steel split sleeve Repair Clamps are structured utilizing the most recent headways in class to streamline the creation procedures and parts, bringing about decreased weight, lower bowing rates, and an undeniably satisfactory piece.

DESIGN STANDARDS

Both metal parts: Inoxidable steel AISI 304 or AISI316L, passivated.

Double band (two areas), with a working width of 20-22 mm, contingent upon the distance across.

V gasket, steel-fortified to frame the chamber.

Premium NBR elastic chokes.

Countries We Deliver To

United States, Indonesia, China, Pakistan, Brazil, Nigeria, Bangladesh, Russia, Mexico, Japan, Ethiopia, Philippines, Egypt, Vietnam, Dr Congo, Germany, Turkey, Iran, Thailand, United Kingdom, France, Italy, South Africa, Tanzania, Myanmar, Kenya, South Korea, Colombia, Argentina, Spain, Uganda, Ukraine, Algeria, Sudan, Iraq, Afghanistan, Poland, Canada, Morocco, Saudi Arabia, Uzbekistan, Peru, Malaysia, Angola, Ghana, Mozambique, Yemen, Nepal, Venezuela, Madagascar, Ivory Coast, Cameroon, North Korea, Australia, Taiwan, Niger, Sri Lanka, Burkina Faso, Mali, Romania, Chile, Malawi, Kazakhstan, Zambia, Guatemala, Ecuador, Netherlands, Syria, Senegal, Cambodia, Chad, Somalia, Zimbabwe, Guinea, Rwanda, Benin, Tunisia, Belgium, Burundi, Bolivia, Cuba, Haiti, South Sudan, Dominican Republic, Czech Republic, Greece, Portugal, Jordan, Azerbaijan, Sweden, United Arab Emirates, Honduras, Belarus, Hungary, Tajikistan, Austria, Papa New Guinea, Serbia, Switzerland, Israel, Togo, Sierra Leone, Hong Kong, Laos, Paraguay, Lebanon, Bulgaria, Libya, Nicaragua, El Salvador, Kyrgyzstan, Turkmenistan, Singapore, Denmark, Finland, Slovakia, Republic of Congo, Norway, Palestine, Oman, Costa Rica, Liberia, Ireland, New Zealand, Central African Republic, Mauritania, Panama, Kuwait, Croatia, Moldova, Georgia, Eritrea, Uruguay, Bosnia And Herzegovina, Mongolia, Armenia, Jamaica, Puerto Rico, Albania, Qatar, Lithuania, Namibia, Gambia, Botswana, Gabon, Lesotho, Macedonia, Slovenia, Guinea Bissau, Latvia, Bahrain, Trinidad And Tobago, Equatorial Guinea, Estonia, Timor Leste, Mauritius, Cyprus, Swaziland, Djibouti, Fiji, Reunion, Comoros, Guyana, Bhutan, Solomon Islands, Macau, Montenegro, Luxembourg, Western Sahara, Suriname, Cape Verde, Maldives, Malta, Brunei, Guadeloupe, Belize, Bahamas, Martinique, Iceland, Vanuatu, French Guiana, Barbados, New Caledonia, French Polynesia, Mayotte, Sao Tome And Principe, Samoa, Saint Lucia, Guam, Curacao, Kiribati, Micronesia, Grenada, Saint Vincent And The Grenadines, Aruba, United States Virgin Islands, Tonga, Seychelles, Antigua And Barbuda, Isle Of Man, Andorra, Dominica, Cayman Islands, Bermuda, Marshall Islands, Northern Mariana Islands, Greenland, American Samoa, Saint Kitts And Nevis, Faroe Islands, Sint Maarten, Monaco, Turks And Caicos Islands, Liechtenstein, Saint Martin, San Marino, Gibraltar, British Virgin Islands, Palau, Cook Islands, Anguilla, Tuvalu, Wallis And Futuna, Nauru, Saint Barthélemy, Saint Pierre And Miquelon, Montserrat, Falkland Islands, Niue, Tokelau, Vatican City