Reli Sleeves is a known trading unit of Flow Conditioner, which come in various thickness and dimension to suit the requirement of our clients. The Flow Conditioner is a device that further develops the fluid velocity profile across the flow section. Flow conditioner reduces disturbances and furthermore allows a decent redistribution of the speed profile, at each mark of the section of the pipe. In this manner, these gadgets make it conceivable to reduce the upstream straight lengths and improve the measurement accuracy in the case of flow measurement.

MAIN FEATURES

- Standard: ISO 5167, ASME MFC-3M.

- Fluid: liquid, gas, steam.

- Solder (BW) or flanged connection

- Different types: tube bundleflow straightener, AMCA or “Star” straightener, Gallagher, K-Lab Nova, NEL, Sprenkle or zanker flow conditioner.

Properties of our Flow Conditioner Plates

At Reli Sleeves the ideal flow profile for the Flow Conditioner plates can ordinarily be accomplished while having a distance of 15 to 25 pipe diameters of straight run upstream of the meter, following a single elbow. For greater distances, there are other pipe geometries that are expected. Although, in a real-world application, constant

Materials used for our Flow Conditioner Plates

ASTM specifications are followed to manufacture half repair sleeves from superior quality carbon steel plates. Structural quality carbon steel or pressure vessel quality carbon steel is used according to the usage and requirement of the client in the below-mentioned grades:

Types of Flow Conditioner Plates

There is a wide range of Flow Conditioner Plates manufactured by Reli Sleeves that are used as per the requirements for the utilization;

- Zanker Type

- Tube Type

- Folded Vane

- Fin Type

- Disturbance Plate (Sprenkle)

Vortab Type

Read MoreFlow Conditioning Plates Features

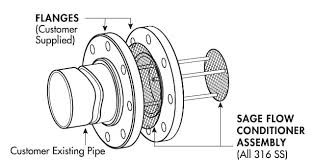

Minimizes low profile anomalies caused by elbows, valves, expansions, and reductions. Essentially diminishes upstream and downstream funnelling necessities. Low-pressure drops. Accessible in sizes for 1″ to 14″ plan 40 lines (larger sizes contact facility). Rugged 316 ss development. Easy installation using customer supplied flanges

Advantages of the said product

Reli Sleeves manufactured Flow Conditioner in Flow Measurement

With flow measurement, we cannot simply stick a flow meter in the pipe, turn it on and expect perfect results.

In the real world one has to deal with these:

Industries that make use of Flow Conditioner Plates

Reli Sleeves manufactured Flow Conditioner Plates are not exclusive for Petrochemical, Marine or just Oil and Gas Industries, they have uses in other industries as well. Food Processing Industries, Breweries and Refineries, Ship Building and Nuclear Power Plants, are some of the many industries that make full use of the Flow Conditioner Plates manufactured at Reli Sleeves.

Conclusion

With the sufficient use of the Reli Sleeve’s Flow Conditioning Plates of straight pipe length, the effect of the disturbances caused during flow can be effectively handled in the upstream of the meter. Even so it is not a fool proof solution nor is it always practical guaranteed solution. For such impractical situations, the use of flow conditioners is utilized for shortening the requirements of the upstream pipe runs. The use of Flow Conditioners or Straighteners are effective in the elimination of the swirls and helping in the restoration of the grossly accurate flow measurement.

Marking and Shipping

All Flow Conditioner Plates are marked for the size, dimension and grade of the materials used in the manufacture of the Flow Conditioning Plates. Reli Sleeves Pipes avails the Flow Conditioner Plates all across India and various countries abroad as well.