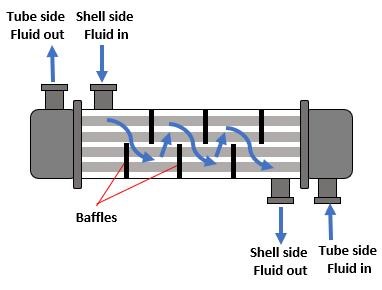

Reli Sleeves is a known trading unit of Baffle Plates, which come in various thickness and dimension to suit the requirement of our clients. A baffle plate is a plate or mechanical device intended to control or direct the progression of a liquid. Reli Sleeves is a leading manufacturer of baffles plates. Our baffle plates are parts of shell and tube heat exchangers which are utilized to help and fix the tubes in a defined position. Vibration stability can be improved by introducing Reli Sleeves baffle plates and having them installed to secure the component where they are used.

Reli Sleeve offers a complete line of full encirclement steel sleeve that

Read More

In Shell and Tube heat exchangers, Reli Sleeves baffles are utilized to build the turbulence of the flow.

Properties of our Baffle Plate

In Shell and Tube heat exchangers, Reli Sleeves baffles are utilized to build the turbulence of the flow. Having high turbulence implies a higher Reynolds number which is straightforwardly corresponding to the heat exchange coefficient and their relationship is given by Dittus-Boelter’s condition. The more prominent the heat transfer coefficient, the higher the hotness move rate. So essentially, so especially baffle plates manufactured by Reli Sleeve are utilized in heat exchangers to build the heat transfer rate.

Reli Sleeves Baffles support the tubes in the shell of a shell and tube heat exchanger as well as controlling flow heading around the cylinders and expanding the turbulent flow of the shell side liquid expanding to the heat transfer.

Reli Sleeves manufacture the baffle plates that are used in the heat exchanger give the required direction to the liquid for a successful heat transfer process. With appropriate direction, the expected liquid interacts with another liquid with which the heat transfer process is to accomplished

Materials and Grades used for our Baffle Plate

ASTM specifications are followed to manufacture half repair sleeves from superior quality carbon steel plates. Structural quality carbon steel or pressure vessel quality carbon steel and various other materials are used according to the usage and requirement of the client in the below-mentioned grades.

Read MoreTypes of Baffle Plate

Different types are used in heat exchangers, below are the popular ones

- Segmental baffles

A plate-type baffle might be single segmental, twofold segmental, or triple segmental. The single and twofold segmental baffles are most often utilized as they redirect the flow most actually across the tubes.

Read MoreAdvantages

One common issue that emerges in blending and mixing is an undesirable flow pattern. If the blending is creating an undesirable flow pattern, one might experience issues with thorough blending and the arrangements that would be added, particularly there is a mix of liquids and solids. It won’t make any difference even if there is adequate power, as all the mixer can do is accelerate the fluid around and around for the blending process.

Luckily, there is an unquestionably simple fix for fixing an undesirable flow pattern and improving your mixing process: installing Reli Sleeves manufactured Baffle Plates.

Industries that make use of Baffle Plate

Reli Sleeves manufactured Baffle Plates are not exclusive for Petrochemical, Marine or just Oil and Gas Industries, they have uses in other industries as well. Food Processing Industries, Breweries and Refineries, Ship Building and Nuclear Power Plants, are some of the many industries that make full use of the Baffle Plates manufactured at Reli Sleeves.

Marking and Shipping

Baffle Plates manufactured at Reli Sleeves are marked for the size, dimension, and grade of the materials used in the manufacture of the Baffle Plates. Reli Pipes avails the Baffle Plates all across India and various countries abroad as well.