Cast Basalt is a mineral of exceptionally high abrasion resistance, unlimited resistance to moisture, high compressive strength and resistance to virtually all acids and alkalis and is completely corrosion free. Cast blast is produced by melting selected natural basalt broken into sizes of 20-50 mm in shaft furnaces at temperatures around 1,300C, following by casting at which the melted basalt forms uniforms pherolithic crystals hence producing its typical physical properties, in particular its exceptional hardness and wear-resistance.

Read MoreCeramic Lined Equipment and Bends:

Hard & Compact Smooth & Inner Withstands High-Abrasion & Corrosion In any of the process industries especially Sled and Cement corrosion and abrasion lead to significant downtime of the plant. Further, the useful life or the equipment itself may get impaired because of the high abrasive nature of the materials being used. Thus, ‘wear mechanism’ results in hut down, replacement, etc., which is costly, resulting in loss to tilt: tunic of millions of rupees.

Characteristics:

- High resistance to all types of chemicals

- High resistant to sliding abrasion

- Non weld ability & smooth surface results ill easy How of materials.

- Can With stand and temperature up to 200 C.

- Smooth Surface and resistant to abrasion & corrosion

| Material | Thickness(mm) | Approx. Life ( Months ) |

|---|---|---|

| Mild Steel | 10 | 3-5 |

| Cast Iron | 20 | 6-8 |

| Ni-Hard | 20 | 12-14 |

| Cast Basalt | 30 | 20-25 |

| Ceramic | 10 | 35-40 |

Ceramic Lined Equipment and Bends:

Hard & Compact Smooth & Inner Withstands High-Abrasion & Corrosion In any of the process industries especially Sled and Cement corrosion and abrasion lead to significant downtime of the plant.

Read MoreTechnical Details:

- Friction Resistance: As more material is passed over Cast Basalt, it gets polished up thereby reducing friction further. Cast Basalt improves in service after getting polished. Wetting also improves its performance in practical applications.

- Impact Resistance: Direct Impact Resistance at a perpendicular angle is low like all other ceramics, but it can be increased with proper installation by reducing the angle of impact. Cast Basalt can be used to mitigate sliding abrasion. Moreover, external impact strength of composite basalt pipe (enclosed in M.S. Shell) is always more than that of bare Ni-hard Pipe.

- Chemical Resistance: Cast Basalt is almost absolutely acid/alkali resistant (except Hydrofluoric Acid) and hence corrosion resistant.

- Weight and Sizes: Basalt Tiles are available in regular shape square of 200 x 200 x 30 mm thick, weighing approximately 90 kg/sq. m; whereas bends and pipes are lined using Basalt Cylinders of various standard sizes from 50NB up to 500NB.

- Temperature: Cast Basalt withstands temperature up to 450ºC.

- Life: Life of basalt-lined pipe is estimated to be 7 to 10 times that of Cast Iron, and 3 to 4 times that of Ni-hard Steel.

Specifications:

- Specific Gravity : 2.8 to 3.1 gm/cm3

- Compressive Strength: Minimum 4500 kg/cm2

- Hardness: 8 as compared to 10 of Diamond Moh’s Scale.

- Abrasion: 0.4 mm material loss (max.)

Applications Area:

- Thermal Power Stations: Raw Coal Chutes/ Hoppers, Feed Bunker/Coal Bunker, Ash Pits, Crushers, Bottom Ash, Disposal Slurry, Dust Lines/ Bends, Pipeline/Bends, Fly Ash. Trenches below Hopper and pipelines, Pulverized Coal Piping

- Cement Plants: Dynamic Air Separators, Raw Mill Ducts/ Chutes, Drag Chain Conveyor, Grate Cooler Housing, Air Separator/ Cyclones, Coal Handling, Coal Hopper/ Chutes, Cement Conveying, Slurry Lines/ Bends Lines/ Bends, Discharge Boxes / Bankers, Lime/Silica Hoppers/Chutes, Chain Conveyor Housing, Mixers/Nozzles, Coal Venturi, etc.

- Steel plants: Coke sorting unit, Coal bunkers / sinter bunkers, Lime bunkers, Coke breeze, Sinter plant cyclones, Sinter plant flow conveyors, Iron slurry line, Thick slurry lines, Air lift pipes, Telescopic pipes, Granulated slag, Hot mill flume, etc.

- Coal Washer: Coal Washing Plants, Coal Transportation, Conveyor Chutes/Pipes, Floatation Cells, Media Sumps, Centrifuges, Cyclones, Sieves etc.

Technical Details:

- Friction Resistance: As more material is passed over Cast Basalt, it gets polished up thereby reducing friction further. Cast Basalt improves in service after getting polished. Wetting also improves its performance in practical applications.

Cast Basalt Lined Ash Pipeline

We hold expertise in fabricating and supplying of a qualitative range Cast Basalt coated Ash Pipelines. Our pipelines are designed and developed by experts to ensure durability and also to meet International Quality Standards. Our Ash Pipelines are coated with Cast Basalt to prevent abrasion because cast basalt is one of the most frequently used wear protection materials. The range of Ash Pipelines made by us are highly acknowledged in the market due to their excellent performance and salient features including excellent wear & tear, durability, reliability, high strength, and cost-effectiveness.

Cast Basalt Lined Ash Bends

At Reli Sleeve, we lined up Ash bends with Cast basalt because is wear resistant and makes the bends more durable. It possess superior properties such as Hardness (7 to 8 MOH), Scale Compressive Strength (4500 Kg/Sq. cm), Abrasive Resistance (0.06 – 0.08 cm) Bending Strength (300 Kg/Sq. cm), Temperature Limit (350°C) and nil Water Absorption. Due to such properties it is more preferable lining than others. These Cash Basalt coated Ash bends find application in various industries. Moreover, these are highly acknowledged for their salient features such as: high strength, durability, excellent wear & tear, and reasonable prices.

Available Variants :

- Small ID Bend (upto ID 450mm)

- Large ID Bend (greater than ID 450mm

Cast Basalt Tiles

We offer Cast Basalt Tiles for Coal Bunkers and Chutes. These cast basalt tiles are bedded as well as jointed in cement/special bonding agents like resins depending upon application. These tiles mostly find application in automotive industry and are designed to provide long-lasting lining and enhancement to involved operational life cycle for both plant as well as equipment. Other than automobiles, some of the other industries where these are used in include:

Available Variants :

- Power

- Coal

- Steel

- Cement

- Pulp & Paper

- Mineral Processing

Advantages:

- Utilizing Cast Basalt enhances and improves operational life of plants

- These are best suited for jobs where extensive cutting is needed

- We can also deliver pre-cut tailored tiles based on the considerations of vibration, impact and other factors at client’s end

Liners

Following types of liners are under our production range:-

1.Trench Liners

Trench Liners have proven to be the perfect solution of erosion problems. The trench liners are custom fabricated according to the specific dimensions of each trench to facilitate installation.

2. Hexagonal Liners

Hexagonal and small square tiles ranging from 10 sq. mm to 20 sq. mm in thickness ranging from 5mm to 15mm are manufactured form small curves and fast In-situ application. In case of high impact conditions, Hexagonal Tiles with Rubber Armour is provided.

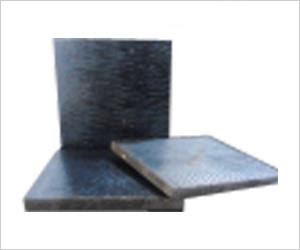

3. Rectangular Plates/Tiles

Various types of rectangular plates or tiles are under our manufacturing range