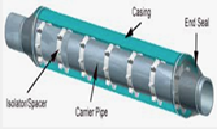

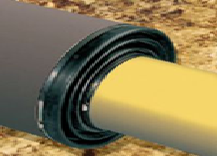

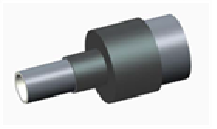

The Casing Pipe and Carrier pipe is Wrapped around by Neoprene rubber end seal then compressing the adhesive applied strips edge. Two SS 304 heavy duty worm strap is fastened to fit tightly.

Pipe sizes from 2″ to 42″ are available for a horizontal or vertical application.

| END SEAL TYPES: | |

| PROFILE CUT TO REQUIRED SIZE AND PASTE THE SEALING EDGES BY ADHESIVE. | MOULDED |

| MATERIALS : |

| EPDM Rubber ( generally 3 mm ) are used for Moulded type end seal, mostly waterworks, |

| Stainless-steel heavy duty worm strap, |

| Silicone for high temperature applications |

| NBR for oil and gas applications |

PRODUCT PROPERTIES: Moulded type

| Test Detail | Specification | Result |

| Polymer | EPDM | EPDM |

| Hardness | 70±5 | 72 |

| Tensile Strength MPA Minimum |

10 | 10.6 |

| Elongation % Min. | 200 | 300 |

| Ageing Resistance at 100°C/70 Hrs. |

Hs : +7 T.S. Chage Rate : -25% Elg Chage Rate : -25% Within |

Hs : +4 Ts : +1% Elg : -20% |

| Compression Set At 100°C/22 Hrs. | Max. 50% | 30% |

Wrap Type End Seal Properties

| Test Detail | Specification | Result |

| Polymer | Natural Rubber | |

| Surface | Both Side Smooth Finish | |

| Colour | Black | |

| Thickness (mm) | 3.00±0.3 | 3.10 |

| Specific Gravity gm/cc | 1.60±0.05 | 1.59 |

| Hardness Shore A | 70±5 | 70-71 |

| Tensile Strength in Kg/Cm2 (Min) | 30 | 36 |

| Elongation at Break % (Min) | 250 | 290 |

| Temperature Limits | -20°F to 170°F |

| Color | Black |

| Finish | Smooth |

| Durometer ‘A’ | 70 +/- 5 |

| Average Tensile | 1000 PSI |

| Average Elongation | 350% |

IMPORTANT FEATURES AND BENEFITS

- Casing End Seal is used for watertight sealing the annular space between casing pipe and carrier pipe at casing ends.

- Protects against insulation damage or leakage from moisture, water and contaminants.

- It is resistant to heat, cold, vibration, impact, abrasion, corrosive fluids, disbanding, organic and bio-deterioration.

- End seal are designed to address both angular and concentric misalignment of casing pipe without losing the sealing efficiency.

- Wrapped End seal are used for Custom as well as all Standard Pipe Size combination.

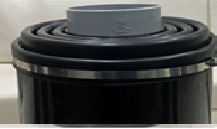

- Moulded type End seal are used for a combination of a very large casing pipe to smaller carrier pipes. Seals stretch 7% for size fitting.

- Moulded type End seal allow large thermal expansion and contraction movement most of the flex boot is contained inside the casing pipe. Several arc folds allow pipe to casing movement as required for the application.