Flange Repair Clamps – Stop leaks in flange gaskets

Flange Repair clamps units are a permanent repair clamps for leaking flange gasket. The unit is installed without taking the line out of service.

Flange Repair Split+Sleeve can fully encompass a flange set, stopping the leak by sealing on the pipe beyond the flange welds. Our solution has the ability to cover a wide variety of flange types and classes for both onshore and offshore applications. It is safe, easy to install, and can be welded while the line is in service

Flange Fit Flange Repair Clamp

- Stops leaks in flange gaskets

- Flange Fit Repair Rings are designed for easy installation.

- No special surface preparation is required prior to installation.

- The product can be installed by your own personnel and can be used multiple times.

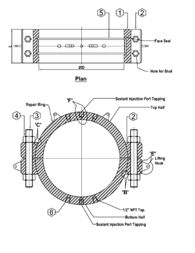

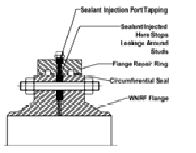

- Bolt leakage is stopped by the injection of a suitable sealant fluid via sufficient injection sockets.

- In case of a small gap between the line flanges, gaskets can be installed for temporarily sealing prior and during injection.

- Detailed design is done based on line temperature, design temperature and design pressure.

- In order to be able to quote the correct product, please download and complete the Flange Fit Data Sheet from our website and send it to us.

- Clamps are hydrotested as per ANSI class at 1.3 x operating pressure.

- No special flange surface preparation is required, no costly shutdowns for installation.

- Company maintenance personnel can install flange repair clamps. Other than cleaning the flange, existing flanges are not altered.

- On scheduled shutdown maintenance the flange repair clamp can be removed and the gasket replaced. The unit may put back in service or held in stores for future repair.

- Injection sockets are utilized to seal the compartment fully. In case of a small gap between the line flanges, gaskets can be installed to temporarily seal the gap before and during injection.

Material Specification

| Pipe Sizes | 1″ & Above |

| Split Body Shell | SA / ASTM A 516 Gr. 70 ASTM A 106 GR A, B, C Seamless Pipe ASTM A516 Gr. 70 Steel Plate API 5L Gr B, X42, X46, X52, X56, X60, X65, X70 ASTM A36 ASTM A572 Gr42, Gr50, Gr55, Gr60, Gr65 ASTM A516 Gr55, Gr60, Gr65, Gr70 ASTM A537 Class 1, Class 2, Class 3 EN 10025 ASTM A216 WCC ASTM A352 LCC ASTM A216 WCB Any other as per client requirement. |

| Body Flange (Stiffner) | SA / ASTM A 105 Any other as per client requirement. |

| Stud & Nut | SS-316 / Pilot Hole SS 316 or as per client requirement ASTM A 193 Gr. B7, with A194 Gr 2H or as per client requirement Nuts. ASTM A 194 Gr2.2H, 2HM, 4, 7, 7M, 8, 8M ASTM A307 Gr A, B, C ASTM A320 Gr L7, L43 ASTM A325 Gr Type 1,Type 2,Type 3 Any other as per client requirement. Coating :Yellow Epoxy Polyamide, Standard or Marine Epoxy Galvanized, PTFE, Xylan Coated or any other as per client requirement |

| Seals< Gaskets | NBR temperature range is from -20°C to +80°C Viton temperature range is from -20°C to +200°C Silicone, Kevlar, Hycar HNBR temperature range is from -20°C to +150°C Any other as per client requirement |

| Vent Plug | SA / ASTM A 105 |

| Lifting Plug | SA / ASTM A 516 Gr. 70 |

| Sacrifical Anode | Zinc Alloy Any other as per client requirement. |