Reli Sleeve offers a total line of Half Pipe Soles that permit pipeline owners and operators to make sure about deficient areas of channel that are broken, consumed (inside or remotely), imprinted, harmed, or spilling. The item is a metal wrap situated around the channel for support and to keep up the weight inside. The Half Pipe Soles is fabricated by welding together two half sleeves around pipe. These Half Pipe Soles are just allowed to be introduced on pipe having a divider thickness somewhere in the range of 0.188 and 0.750 inches.

Read More

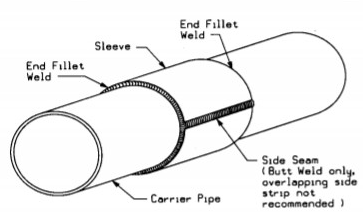

The sleeve comprises of two parts of a chamber of channel or two suitably bended bits of plate that are set around the transporter pipe at the harmed territory and subsequent to situating, are joined by welding.

Type A Sleeve

Type A Sleeve Ends are not Circumferentially welded to the Carrier shaft. The sort A sleeve can not hold an interior weight yet goes about as a defective region fortification. It is utilized uniquely for fixing absconds that are not spilled and which are not expected to increment during activity or in full understanding of the harm and the development rate.

Type A Sleeve is made of two bended steel plates or two-chamber pipes enclosed by the broken pipeline and associated with Welded Side creases in the wake of situating.

Type B Sleeve

Type B Sleeve closes are circumferentially welded to the bearer plate. A sleeve type B can withstand inner weight as the finishes are offered to the bearer tubing. Sleeve type B might be utilized to fix spillage deformities or imperfections that may in the end spill and to improve the funnel’s pivotal burden conveying limit. The finishes of a sleeve of type B are provided to the bearer pot. In the event that the finishes of the transporter pipe are associated, a sort B channel might be utilized to address the spillage and fortify circumferential imperfections.

Read MorePRINCIPAL OPERATION OF HALF PIPE SOLES

The early work by Battelle indicated that steel sleeves are powerful on the grounds that they control swelling, or gathering of strain, in the damaged zone while engrossing just 15 to 20 percent of the circle worry in the transporter pipe. Steel sleeves are viable on the grounds that the firmness (versatile modulus) of the sleeve material is proportionate to that of the line pipe steel.

Read More

ADVANTAGES AND DISADVANTAGES OF HALF PIPE SOLES

One of the guaranteed focal points of composite fixes over steel sleeves is that their establishment requires no welding to an in-administration pipeline. It is obvious from the conversation over that the establishment of Type A sleeves, which can fill a similar need as composite fixes, likewise requires no welding to an in-administration pipeline. Welds that don’t contact the bearer pipe are not viewed as “÷in-administration’ welds as indicated by Appendix B of API 1104, despite the fact that longitudinal crease welds are made while the pipeline is in-administration.

Read More

WELDING ONTO AN IN-SERVICE PIPELINE

A burn-through, or victory as it is now and then alluded, will happen when welding onto a pressurized pipe if the unmelted zone underneath the weld pool has lacking solidarity to contain the interior weight of the funnel (see Figure 6). A burn-through normally brings about a little pinhole in the base of what was the weld pool. The danger of burn-through will increment as the funnel divider thickness diminishes and the weld infiltration increments.

Read More

HALF PIPE SOLES (FULL WRAP)

A full enclosure sleeve (full wrap) is a metal wrap introduced around the pipe for fortification and containing pressure. The full sleeve is delivered by welding together two half sleeves around the pipe. Sleeves are just allowed to be introduced on a pipe having a divider thickness somewhere in the range of .188 and .750 inches.

Read More

PROPERTIES OF HALF PIPE SOLES

There are two essential classes of full-circle steel sleeves: Type An and Type B.There are two fundamental issues with welding onto in-administration pipelines, be it for fitting fix sleeves or introducing a branch association preceding “hot tapping”. The first being “consume”, where the channel divider gets infiltrated because of the welding curve. The subsequent issue is called as hydrogen breaking since welds made in-administration cool at an expanding rate in light of the capacity of the streaming substance to extricate the warmth from the funnel divider.

Read MoreMATERIALS USED FOR HALF PIPE SOLES

The material of the Half Pipe Soles given by Reli Pipes is ensured. Every half-sole segmentis comprehensive of one pre-pleated back-up strip. Half Pipe Soles are accessible in four sorts of material, two weight appraised prepares and two basic evaluation steel. The weight evaluated steel sleeves are used for fixing spilling and non-spilling harms while the basic evaluation steel sleeves can be utilized as a fortification for the harmed territory.

| 1.0035 S185 | 1.0038(dubl) S235JR |

| 1.0044 S275JR | 1.0045 S355JR |

| 1.0050 E295 | 1.0060 E335 |

| 1.0070 E360 | 1.0114 S235J0 |

| 1.0116(dubl) S235J2(+N) | 1.0117 S235J2 |

| 1.0143 S275J0 | 1.0144 S275J2(+N) |

| 1.0145 S275J2 | 1.0553 S355J0 |

| 1.0570(dubl) S355J2(+N) | 1.0577 S355J2 |

| 1.0590 S450J0 | 1.0595 S355K2(+N) |

| 1.0596 S355K2 |

| EN 10025-3: 2004 Hot rolled products of structural steels. Technical delivery conditions for normalized/normalized rolled weldable fine grain structural steels COMPARE GRADES |

| 1.0490 S275N | 1.0491 S275NL |

| 1.0545 S355N | 1.0546 S355NL |

| 1.8901 S460N | 1.8902 S420N |

| 1.8903 S460NL | 1.8912 S420NL |

| EN 10025-4: 2004 Hot rolled products of structural steels. Technical delivery conditions for thermomechanical rolled weldable fine grain structural steels COMPARE GRADES |

| 1.8818 S275M | 1.8819 S275ML |

| 1.8823 S355M | 1.8825 S420M |

| 1.8827 S460M | 1.8834 S355ML |

| 1.8836 S420ML | 1.8838 S460ML |

| EN 10025-5: 2004 Hot rolled products of structual steels. Technical delivery conditions for structural steels with improved atmospheric corrosion resistance COMPARE GRADES |

| 1.8945 S355J0WP | 1.8946 S355J2WP |

| 1.8958 S235J0W | 1.8959 S355J0W |

| 1.8961 S235J2W | 1.8963 S355J2W(+N) |

| 1.8965 S355J2W | 1.8966 S355K2W(+N) |

| 1.8967 S355K2W |

PRODUCTION OF HALF PIPE SOLES

Reli Sleeve fabricates Half Pipe Soless from the most noteworthy evaluation carbon steel material. We produce this top notch quality item by moving, bite the dust framing and step slowing down and consequently they never experience heat treating.Thus making our mastery and procedure extraordinary and preeminent most in the business.

CUSTOMISATION OF HALF PIPE SOLES

We slant the longitudinal edges of the channel for welding if a customer explicitly requests it. Half Pipe Soles closures have shaved square edges to empower filet welding, albeit square end slope can likewise be made according to customer detail. Our channel sleeves are made with just those carbon steel plates having low carbon equivalency to guarantee great weldability. We can make Half Pipe Soless in any custom steel grades and of any size according to the application and prerequisite of the client.

Read MoreTechnical Specification of HALF PIPE SOLES

| Sleeve Size | 06″ NB to 64″ NB |

| Sleeve Thickness | As per Client Requirement, or min Carrier Pipe Thickness. |

| Sleeve Length | 100 MM to 3000 MM, as per Client Requirement. |

| Sleeve Edges | Milled Groove or Plain |

| Backing Strips | Yes we Supply along with the Sleeve min Thickness 1.6 mm |

| Carrier Pipe Size | 2″ NB To 64″ NB (Nominal Bore Size) |

| Carrier Pipe Wall Thickness | Schedule 10 To Schedule XXS (Heavier On Request) |

| Specification and Grades | ASTM A53 Grade B, ASTM A106 Grade B, ASTM A106 Grade C, ASTM A333 Grade 6, API 5L X42 PSL1/PSL2, API 5L X46 PSL1/PSL2, API 5L X52 PSL1/PSL2, API 5L X56 PSL1/PSL2, API 5L X60 PSL1/PSL2, API 5L X65 PSL1/PSL2, API 5L X70 PSL1/PSL2, API 5L X80, API 5L X100 PSL1/PSL2, PSL1/PSL2, ASTM A671 CC60, ASTM A671 CC70, ASTM A672 C60, ASTM A672 C70 |

| Temperature | -20 to 150F |

| Testing | Destructive, Magnetic Particle, Liquid Penetrate, PMI, Ultrasonic and Radiographic etc. |

| Dimension | All Sleeve are Manufactured and Inspected / Tested to the Relevant standards including ASTM, ASME, API. |

| Packaging | Wooden Pallet / Wooden Box |

| Shipment & Transportation | By Road – Truck / Train, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

MARKING & SHIPPING OF HALF PIPE SOLES

Every Half Pipe Soles is marked for the size, thickness, dimension & grade of the steel used in the manufacture of the Half Pipe Soles. Reli Sleeve avails it’s products all across India and various countries abroad as well.

FEATURES OF HALF PIPE SOLES

- All plates are squared and sheared precisely to close resistances.

- RELI-SLEEVE Soles and Sleeves are framed on our Presses utilizing unique dyes the bucket to guarantee exactness and consistency.

- In the wake of framing all pieces are reviewed to guarantee the nearest potential resiliences for field establishment in the harshest situations.

- Created from high quality steel plate with appropriate carbon substance to guarantee great weld capacity without giving up yield and elasticity.

- Uniquely created to satisfy guideline or uncommon sizes, thickness and material evaluation necessities.

Countries We Deliver To

Countries We Deliver To

United States, Indonesia, China, Pakistan, Brazil, Nigeria, Bangladesh, Russia, Mexico, Japan, Ethiopia, Philippines, Egypt, Vietnam, Dr Congo, Germany, Turkey, Iran, Thailand, United Kingdom, France, Italy, South Africa, Tanzania, Myanmar, Kenya, South Korea, Colombia, Argentina, Spain, Uganda, Ukraine, Algeria, Sudan, Iraq, Afghanistan, Poland, Canada, Morocco, Saudi Arabia, Uzbekistan, Peru, Malaysia, Angola, Ghana, Mozambique, Yemen, Nepal, Venezuela, Madagascar, Ivory Coast, Cameroon, North Korea, Australia, Taiwan, Niger, Sri Lanka, Burkina Faso, Mali, Romania, Chile, Malawi, Kazakhstan, Zambia, Guatemala, Ecuador, Netherlands, Syria, Senegal, Cambodia, Chad, Somalia, Zimbabwe, Guinea, Rwanda, Benin, Tunisia, Belgium, Burundi, Bolivia, Cuba, Haiti, South Sudan, Dominican Republic, Czech Republic, Greece, Portugal, Jordan, Azerbaijan, Sweden, United Arab Emirates, Honduras, Belarus, Hungary, Tajikistan, Austria, Papa New Guinea, Serbia, Switzerland, Israel, Togo, Sierra Leone, Hong Kong, Laos, Paraguay, Lebanon, Bulgaria, Libya, Nicaragua, El Salvador, Kyrgyzstan, Turkmenistan, Singapore, Denmark, Finland, Slovakia, Republic of Congo, Norway, Palestine, Oman, Costa Rica, Liberia, Ireland, New Zealand, Central African Republic, Mauritania, Panama, Kuwait, Croatia, Moldova, Georgia, Eritrea, Uruguay, Bosnia And Herzegovina, Mongolia, Armenia, Jamaica, Puerto Rico, Albania, Qatar, Lithuania, Namibia, Gambia, Botswana, Gabon, Lesotho, Macedonia, Slovenia, Guinea Bissau, Latvia, Bahrain, Trinidad And Tobago, Equatorial Guinea, Estonia, Timor Leste, Mauritius, Cyprus, Swaziland, Djibouti, Fiji, Reunion, Comoros, Guyana, Bhutan, Solomon Islands, Macau, Montenegro, Luxembourg, Western Sahara, Suriname, Cape Verde, Maldives, Malta, Brunei, Guadeloupe, Belize, Bahamas, Martinique, Iceland, Vanuatu, French Guiana, Barbados, New Caledonia, French Polynesia, Mayotte, Sao Tome And Principe, Samoa, Saint Lucia, Guam, Curacao, Kiribati, Micronesia, Grenada, Saint Vincent And The Grenadines, Aruba, United States Virgin Islands, Tonga, Seychelles, Antigua And Barbuda, Isle Of Man, Andorra, Dominica, Cayman Islands, Bermuda, Marshall Islands, Northern Mariana Islands, Greenland, American Samoa, Saint Kitts And Nevis, Faroe Islands, Sint Maarten, Monaco, Turks And Caicos Islands, Liechtenstein, Saint Martin, San Marino, Gibraltar, British Virgin Islands, Palau, Cook Islands, Anguilla, Tuvalu, Wallis And Futuna, Nauru, Saint Barthélemy, Saint Pierre And Miquelon, Montserrat, Falkland Islands, Niue, Tokelau, Vatican City