Split sleeves are widely used for repairing a variety of high or low pressure and high or low-temperature pipeline processes, including oil, water, gas, steam, and chemical. Bolts join the clamp halves to form a high integrity pressure vessel surrounding the damaged or leaking pipe.

Sealing is provided by highest quality molded elastomer seals, selected for compatibility with the product & operating temperature of the pipeline. These sleeves may also be welded to turn out a permanent seal after installation if conditions justify the additional expense.

Split Sleeve are a crucial component of our pipeline integrity products series. The split sleeve product line may be sold separately or as an add-on to larger repair systems in a wide variety of sizes, grades, and arrangements.

Split Sleeve add a new dimension to your timely and permanent pipeline repair work. They are used to repair pipelines of high and low pressure and temperature — offshore and onshore — carrying oil, gas, vapor, chemical process, and water. Click here for API 5L Pipe Sleeve.

PROPERTIES OF SPLIT SLEEVE

The split sleeve clamps are thoroughly statically tested hydro to 1.3 times the working pressure required. All sleeves are prepared with a half-inch vent port, depending on the size and needs & specifications of the client. The sleeves are all made according to the specifications of the API. They correspond to customer specifications & industry specifications design specifications. All of our sleeves are simple to install and maintain. They designed to be easily installed with the most common tools available & readily repairable as well. Our split repair clamps are commercially feasible because they are manufactured using the new technologies, enhancing the low-weight construction techniques and components.

MATERIALS USED FOR SPLIT SLEEVE

Split clamps are made as per the materials required for the clients. The materials used are of impeccable quality which are in accordance to industry specifications. ANSI pressure classes 300, 400, 600, 900 & 1500 are used. Design control and stress analysis are done with body materials suitable for normally corrosive services. Girder rings can also be installed as per the clients’ requirements. Double row sealing design are used in cases where leakage in the pipes are very costly like in the case of pipelines carrying gases.

ASTM A283 GRADES : Grade A , Grade B , Grade C , Grade D.

ASTM A285 GRADES : Grade A , Grade B , Grade C.

ASTM A387 GRADES : Grade A , Grade B , Grade C , Grade D.

SPLIT SLEEVE MATERIAL SPECIFICATIONS

- ANSI pressure classes 300, 400, 600, 900 and 1500

- Design based on: ASME Sec. VIII, API 6H , ANSI B31.4, B31.8 and Split Sleeve Software 3S)

- Design control and stress analysis with Finite Element Package

- Body materials: A216 WCB, A216 WCC, A352 LCC, A516 Gr.70 (Suitable for normally corrosive services)

- Stud material: A193 Gr. B7, Nut material: A 194 Gr. 2H

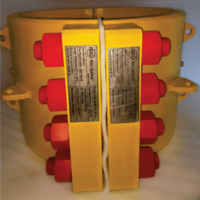

- Coating: Yellow Epoxy Polyamide, standard or Marine epoxy

- The highest quality NBR or VITON elastomer seal precisely compatible with the line fluid and ambient temperature will be installed into the split sleeves

- NBR temperature range is from – 20 C to + 80 ̊ C̊

HNBR temperature range is from – 20 C to + 150 ̊ C̊

VITON temperature range is from – 20 C to + 200 ̊ C - Gaskets are replaceable without any special tools.

- Girder rings can be installed upon cleints request.

- Double Row Sealing (DRS) design is also available.

This special design is more suitable for where probable leakage is much costly or dangerous; such as gaseous services & offshore applications.

WELDABLE SPLIT SLEEVE

All clamps can be fully prepared for welding after installation (welding procedure is available on request).

Heat insulators (parallel to the seals) protect the seals from heat during the welding of the sleeves to the pipe .

PRODUCTION OF SPLIT SLEEVE

After the installation all sleeve clamps may be prepared for welding. During the welding of the sleeves to the pipe heat insulators running parallel to the seals protect them from heat. If ordered by the customers we will make these clamps with longer lengths.

CUSTOMIZATION OF SPLIT SLEEVE

Split sleeve clamps are rendered as per the specifications of the consumer. All the specifications such as body material i.e. carbon steel / stainless steel, studs & nuts for specifications as well as seal materials are of superior quality that is durable & matches the requirements of the customer.

MARKING & SHIPPING

Every sleeve is labeled with the grade of the output of the steel used, scale, thickness & stack. Every product is inspected before shipment and the products that do not match our stringent quality are not shipped with standards. Reli Sleeve avails it’s products all across India and various countries abroad as well.

BENEFITS OF SPLIT SLEEVE

-

-

-

- Can be used when leaking pipes or wall dilution occurs

- They are self-sealing, obtained by screwing clamp studs

- Standard clamps come in single seal arrangement but on request double seal arrangement can be given

-

-

FEATURES

-

- Normal clamps are fitted with a seal made of Buna-Nitrile or Viton made of high quality elastomeric. For such applications the sealing load is accomplished by tensioning the clamp studs with bolts (split sleeve design)All Clamps are designed with an external pressure test facility that prior to commissioning determines the joint integrityTwin seal configuration is also available during installation to allow internal testing.Clamps for both topside and subsea repair applications may be supplied.Read More

DESIGN STANDARDS AND SPECIFICATIONS

-

-

-

- ANSI pressure classes 300, 400, 600, 900 and 1500

- Design based on API 6H.

- Design calculation ASME Sec. VIII Div. I

- Body materials: A216 WCB, A216 WCC, A352 LCC, A516 Gr.70 (Suitable for normally corrosive services)

-

-

DESIGN FEATURES AND METHODS

Safety

The clamps are fully compensating pressure vessels, hydrostatically tested to 1.3 times the rated working pressure (as per the UG-99 clause of ASME Section VIII Div.1)

All Clamps come with a 1 “NPT vent port.

Design Criteria and Industry Standards

Both split sleeves are checked according to API Specification 6H, “End Closure Specification, Connectors and Swivels,” ASME BOILER AND

PRESSURE VESSEL CODE, Section VIII; and, where applicable, with ANSI codes B-31.3, B31.4, & B31.8.

Assurance: EN 10204 3.1

Ease of Installation and Maintenance

All split sleeves are designed for installation with the most common tools available and are readily field repairable, including full replacement of seals.

Economy

Split Sleeve Repair Sleeve is designed using state-of-the-art technologies to refine manufacturing methods and components, resulting in reduced weight, lower bending habits, and a more economical one.

SPLIT SLEEVES ARE COMPATIBLE WITH SOUR ENVIRONMENT

This type of sleeve is designed to be used in hydrogen sulfide (H2S) bearing hydrocarbon service. For sour services, the body material will meet NACE MR0175

CERTIFICATION AND TESTING

Non destructive testing (NDT):

100 % magnetic particle inspection (MPI) for stiffener to shell

weld (fillet)

100 % ultrasonic testing of vent plug welds

100 % MPI of hinge welds

Hydrotest as per ASME Section VIII Div.1 clause UG-99

TECHNICAL DETAILS

- Size: Standard Repair Clamps: 4 – 52″ ≤ 1500# suitable for temporary carbon steel applications

- Size: Engineered Repair Clamps: ½” – 52″ >2500# suitable for temporary or permanent carbon steel, stainless steel and super duplex applications

DESIGN CRITERIA AND INDUSTRY STANDARDS

- All SSRC’s are tested in accordance with the API Specification 6H, “Specification for End Closures, Connectors, and Swivels” and ASME BOILER AND PRESSURE VESSEL CODE, Section VIII, and with ANSI standards B-31.3, B31.4, & B31.8, where applicable. Visions 1 and 2.

- API SPEC 5L, Specification for Line Pipe

- ASME Pressure Vessel Code, Section VIII

- ASME/ANSI B18.2.1, Square and Hex Bolts and Screw Inch Series

MATERIALS

| Material Specification | ||

| Item | Designation | Material |

| 1 | Body Material | A216 WCB, A216 WCC, A352 LCC, A516 Gr.70 |

| 2 | Stud Bolt | A193 Gr. B7 |

| 3 | Nuts | A 194 Gr. 2H |

| 4 | Gaskets | NBR or Viton |

| 5 | Coating | (Marine) Epoxy |

SPLIT SLEEVE CLAMP MATERIAL

| Material: | ASTM A 516 Gr.70 / ASTM A 105 |

| Fasteners: | ASTM-A-193-B7 & ASTM-A-194-2H |

| Seal: | Buna “N‟ |

| Paint: | Epoxy Coating Yellow 100 Microns |

| Vent Port + Plug: | Yes Lifting Lug (8” & above) |

| Hinge Assembly: | (8” & above) Yes |

| Design Temperature: | 65ºC N.D.T. |

| 100% RT Butt Weld | 100% U.T. of vent plug welds. (Fillet) |

| 100% MPI of Hinge welds (Fillet) | |

| Certification: | EN 10204 3.1 |

| Design Calculation: | ASME Sec. VIII Div. |

DESIGN CALCULATION

- ASME-Sec.-VIII-Div.-I,

- Certification-EN-10204-3.1:

NON DESTRUCTIVE TESTING (NDT)

- 100 % magnetic particle inspection (MPI) for stiffener to shell weld (fillet)

- 100 % ultrasonic testing of vent plug welds

- 100 % MPI of hinge welds

- Hydro test as per ASME Section VIII Div.1 clause UG-99

EASE OF INSTALLATION AND MAINTENANCE

- All sleeves are designed to be installed with the most common tools available and can be easily repaired from the field, including a full replacement seal.

- SPLIT SLEEVE INSTALLATION

- Provide enough space to mount the half sleeve in the lower part of the pipe over the word. The minimum distance should be 0.75D.

- Wash the pipe that would have the split sleeve built on.

Grease the surfaces that will be in contact with the gasket of the split sleeve.

-

- Install the upper sleeve in the shortest holes, and the bolts.

- Each half-sleeve on the side is marked. Verify that the marking is on the same sider. Lift the lower sleeve and fit the bolts through the sleeve edge’s thinner section.

- Tighten the bolts, weld the edge of the split sleeve if necessary.

SAFETY

The clamps are fully compensatory pressure vessels, hydrostatically tested to 1.3 times the rated working pressure (as per ASME Section VIII Div.1 clause UG-99)

All Clamps are equipped with a 1” NPT vent port.

ECONOMY

Split Sleeve Repair Clamps are designed utilizing the latest technology , allowing optimization of design techniques and materials, resulting in lower weight, reduced bending tendencies and a more economical product.

DESIGN STANDARDS

All metal parts: stainless steel AISI 304 or AISI316L, passivated.

Double band (two sections) with a working range of 20-22 mm depending on the diameter.

V gasket, steel reinforced to form the pressure chamber.

Standard NBR rubber gaskets.

Countries We Deliver To

United States, Indonesia, China, Pakistan, Brazil, Nigeria, Bangladesh, Russia, Mexico, Japan, Ethiopia, Philippines, Egypt, Vietnam, Dr Congo, Germany, Turkey, Iran, Thailand, United Kingdom, France, Italy, South Africa, Tanzania, Myanmar, Kenya, South Korea, Colombia, Argentina, Spain, Uganda, Ukraine, Algeria, Sudan, Iraq, Afghanistan, Poland, Canada, Morocco, Saudi Arabia, Uzbekistan, Peru, Malaysia, Angola, Ghana, Mozambique, Yemen, Nepal, Venezuela, Madagascar, Ivory Coast, Cameroon, North Korea, Australia, Taiwan, Niger, Sri Lanka, Burkina Faso, Mali, Romania, Chile, Malawi, Kazakhstan, Zambia, Guatemala, Ecuador, Netherlands, Syria, Senegal, Cambodia, Chad, Somalia, Zimbabwe, Guinea, Rwanda, Benin, Tunisia, Belgium, Burundi, Bolivia, Cuba, Haiti, South Sudan, Dominican Republic, Czech Republic, Greece, Portugal, Jordan, Azerbaijan, Sweden, United Arab Emirates, Honduras, Belarus, Hungary, Tajikistan, Austria, Papa New Guinea, Serbia, Switzerland, Israel, Togo, Sierra Leone, Hong Kong, Laos, Paraguay, Lebanon, Bulgaria, Libya, Nicaragua, El Salvador, Kyrgyzstan, Turkmenistan, Singapore, Denmark, Finland, Slovakia, Republic of Congo, Norway, Palestine, Oman, Costa Rica, Liberia, Ireland, New Zealand, Central African Republic, Mauritania, Panama, Kuwait, Croatia, Moldova, Georgia, Eritrea, Uruguay, Bosnia And Herzegovina, Mongolia, Armenia, Jamaica, Puerto Rico, Albania, Qatar, Lithuania, Namibia, Gambia, Botswana, Gabon, Lesotho, Macedonia, Slovenia, Guinea Bissau, Latvia, Bahrain, Trinidad And Tobago, Equatorial Guinea, Estonia, Timor Leste, Mauritius, Cyprus, Swaziland, Djibouti, Fiji, Reunion, Comoros, Guyana, Bhutan, Solomon Islands, Macau, Montenegro, Luxembourg, Western Sahara, Suriname, Cape Verde, Maldives, Malta, Brunei, Guadeloupe, Belize, Bahamas, Martinique, Iceland, Vanuatu, French Guiana, Barbados, New Caledonia, French Polynesia, Mayotte, Sao Tome And Principe, Samoa, Saint Lucia, Guam, Curacao, Kiribati, Micronesia, Grenada, Saint Vincent And The Grenadines, Aruba, United States Virgin Islands, Tonga, Seychelles, Antigua And Barbuda, Isle Of Man, Andorra, Dominica, Cayman Islands, Bermuda, Marshall Islands, Northern Mariana Islands, Greenland, American Samoa, Saint Kitts And Nevis, Faroe Islands, Sint Maarten, Monaco, Turks And Caicos Islands, Liechtenstein, Saint Martin, San Marino, Gibraltar, British Virgin Islands, Palau, Cook Islands, Anguilla, Tuvalu, Wallis And Futuna, Nauru, Saint Barthélemy, Saint Pierre And Miquelon, Montserrat, Falkland Islands, Niue, Tokelau, Vatican City